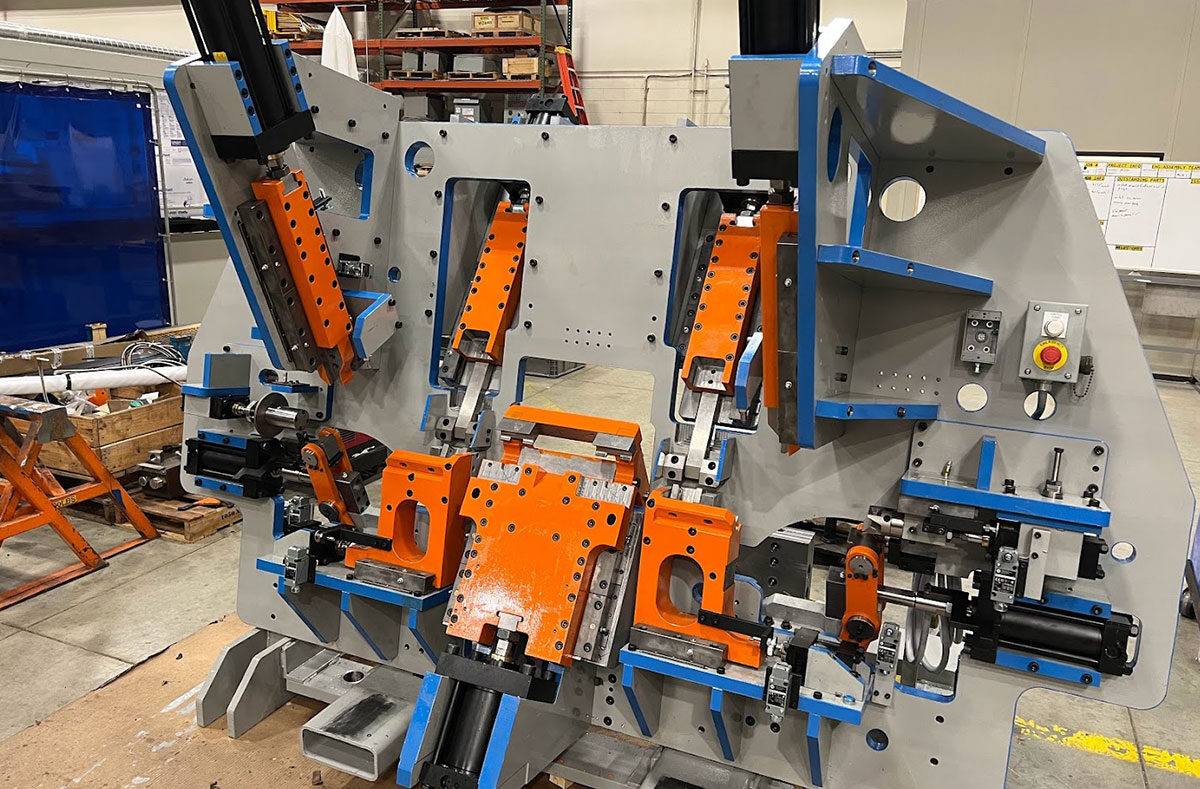

Surface treatment capabilities

Aerospace-grade finishing partners with full documentation and test validation.

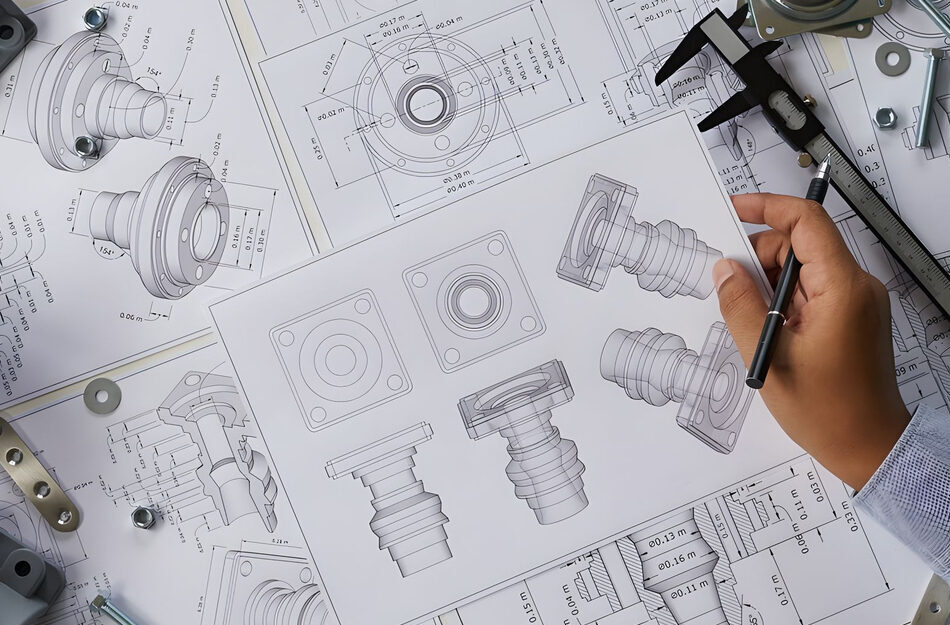

Special Alloys

Aerospace & industrial metals

Aluminum, stainless steels, titanium, Inconel, Monel, Hastelloy, and custom grades.

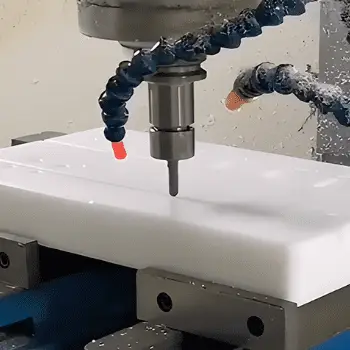

Engineered Plastics

High-performance polymers

PEEK, Nylon, Delrin, ABS, and TPU for precision components and prototypes.

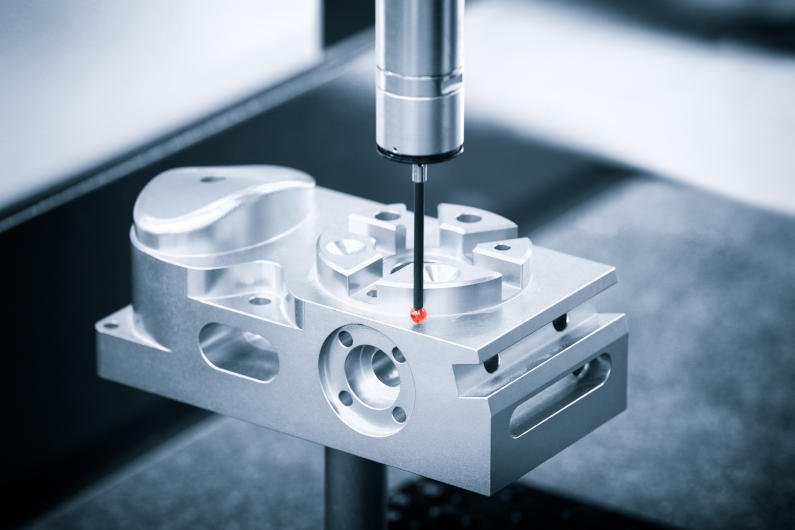

Sourcing & Compliance

AS9100-aligned traceability

Incoming inspection, certification verification, and documented material test reports.